MINING ENGINEERING

LANDFILL

PUBLIC WORKS

HYDRAULIC STRUCTURES

BUILDING CONSTRUCTION

MINING ENGINEERING DRAINTUBE FT

Use

Internal drainage is of vital importance to the safety and reliability of tailings dams. The rate at which the tailings consolidate and the sensitivity of the structure to liquefaction depend almost entirely on drainage.

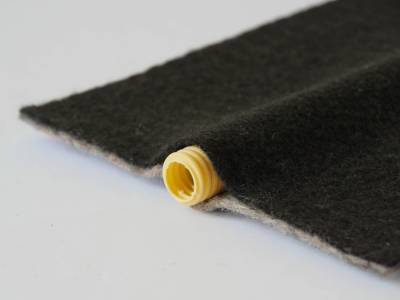

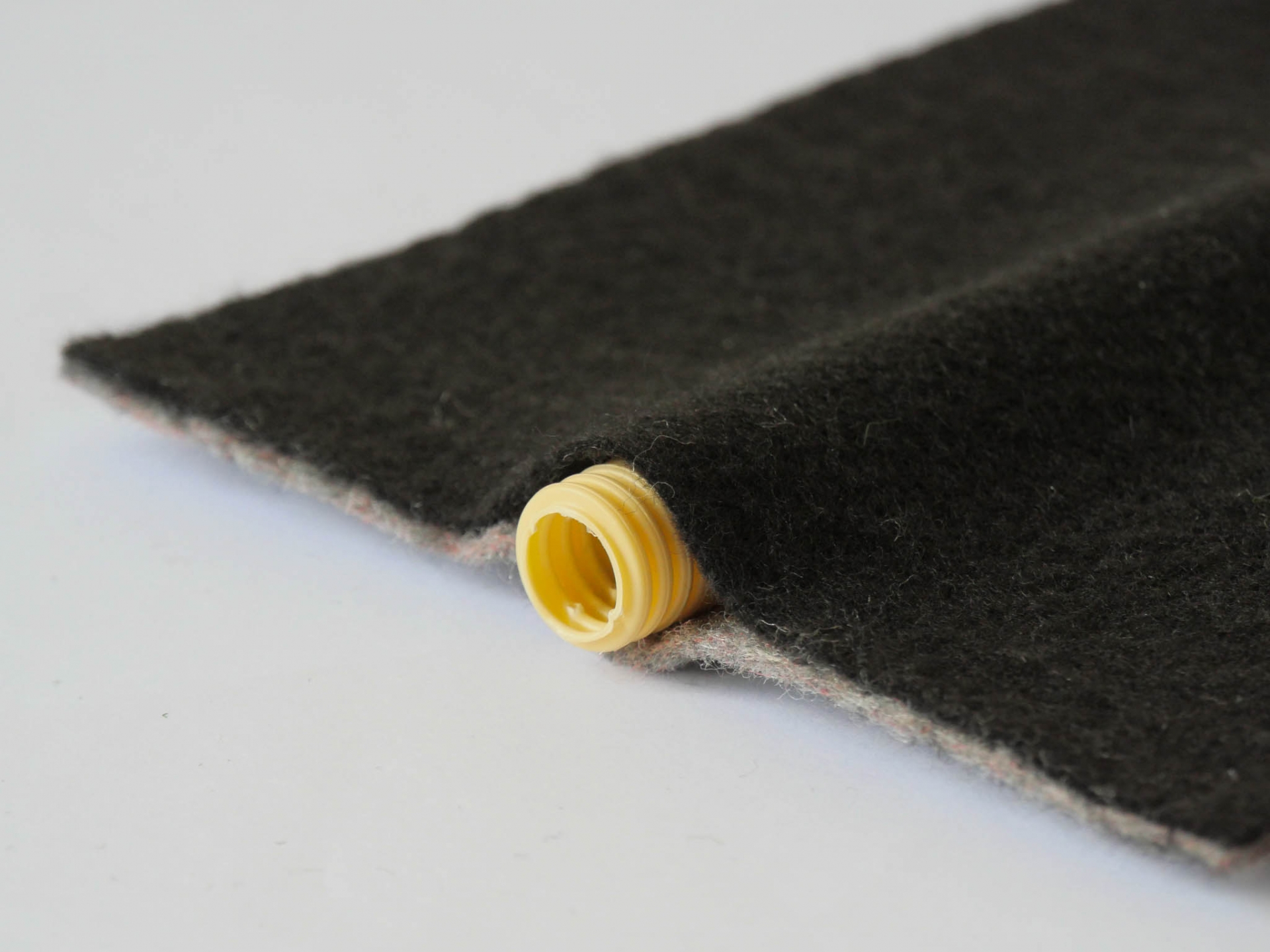

DRAINTUBE® FT geocomposite provides a suitable solution to improve the collection of the water and control the pore pressure. It has a high and stable over time drainage capacity, even under heavy loads.

- At the base of the dam as horizontal drainage blanket, DRAINTUBE® FT lowers the phreatic surface

- At regular intervals into the tailings dam, as finger drains, DRAINTUBE® FT helps reduce the pore pressure and controlling the internal erosion

In addition to being cost-effective and easy to install, it has a better impact on the environment as it replaces granular layers and reduces or eliminates the need to transport these resources.

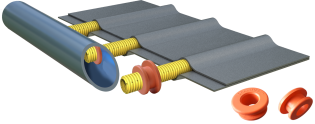

The Quick Connect system connects the mini-pipes of the DRAINTUBE® FT directly to a main collector pipe. This allows for the replacement of the collector trenches when site conditions make their construction difficult. It also permits to better control the outflow.

Benefits

- High drainage capacity under heavy loads

- Improved collection system and phreatic surface control

- Reduced risk of dike failure and better use of tailings to build stable slopes

- Reduced number of collectors or finger drains needed

- Easy installation with a single product to unroll

- Cost-effective and environmentally friendly solution as it replaces granular layers

- Optimisation of existing deposition areas

Features

Drainage

Drainage

Filtration

Filtration

Characteristics

- Polypropylene geocomposite

- Roll width : 3.90 m

- Roll length : 50 m

- 3 diameters of perforated mini-drains : 16 mm, 20 mm and 25 mm

- 4 possible distances between mini-drains : 200 cm, 100 cm, 50 cm and 25 cm